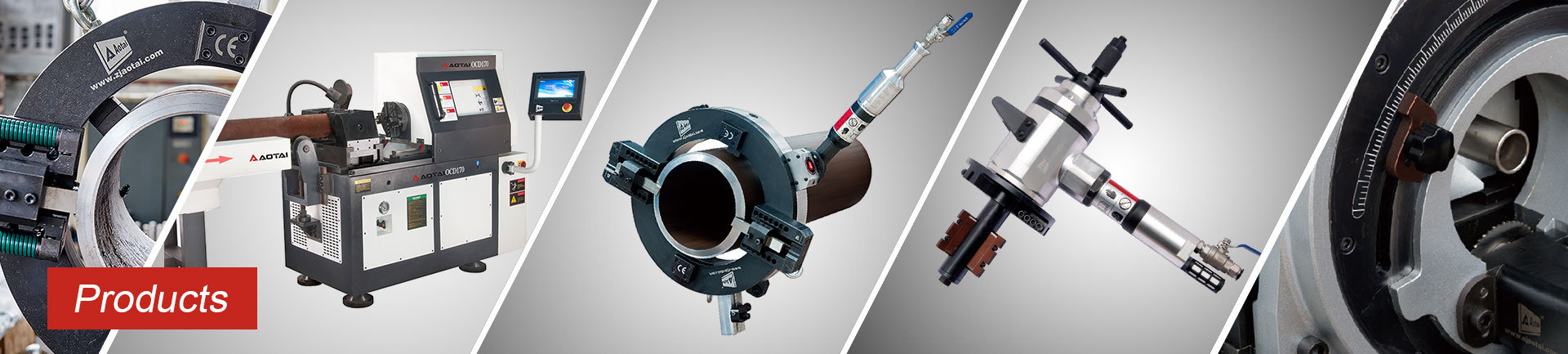

OCD High speed pipe beveling machine:This series of beveling machine tools were developed aims at large quantities of pipe end beveling processing,It is new equipment of pipe prefabrication. Bevel pipe fast, auto-center hydraulic clamping system, can match main machine auto-up/down system to suit different diameter pipes to use, suitable for bevel processing of all kinds of carbon steels, stainless steels, alloy steels, etc. Can bevel different types of shape according to customer’s requirement: U, V, J, Y, X,etc. excellent quality of beveling, efficient working, easy to operate.